0

Porovnat

0

Porovnat

Uživatel

Uživatel

0

Košík

0

Košík

Stacionární fáze

Stacionární fáze pro HPLC

ASTRA - CHROMSERVIS

| Typ fáze | Velikost částic (µm) | Velikost pórů (Å) | Plocha povrchu (m2/g) | % uhlíku | Rozsah pH |

|---|---|---|---|---|---|

| C18-HE | 2, 3, 5, 10 | 100 | 330 | 17 | 2-9 |

| C18-AQ | 2. 3, 5 | 100 | 330 | 13 | 2-9 |

| C18-BDS | 3, 5 | 140 | 170 | 11 | 2-8 |

| C8-HE | 5 | 100 | 330 | 11 | 2-9 |

| C8-BDS | 3, 5 | 140 | 170 | 6 | 2-8 |

| Phenyl-Hexyl-HE | 3, 5 | 100 | 330 | 11 | 2-7.5 |

| DM | 3, 5 | 100 | 205 | 12 | 2-9 |

| Diol | 3, 5 | 100 | 330 | 5 | 2-7.5 |

| Si | 3,5 | 100 | 330 | - | 2-8 |

ARION - CHROMSERVIS

| Typ fáze | Velikost částic (µm) | Velikost pórů (Å) | Plocha povrchu (m2/g) | % uhlíku | Rozsah pH |

|---|---|---|---|---|---|

| Plus C18 | 1.7, 2.2, 3, 5, 10, 15 | 100 | 420 | 18 | 1.5-10 |

| Polar C18 | 2.2, 3, 5, 10, 15 | 120 | 325 | 16 | 1.5-7.0 |

| C8 | 3, 5 | 120 | 325 | 11 | 2.0-7.0 |

| Phenyl-butyl | 2.2, 3, 5 | 100 | 300 | 12 | 1.5-7.5 |

| NH2 | 2.2, 3, 5 | 120 | 325 | 5 | 2.0-6.5 |

| CN | 3, 5, 10 | 120 | 325 | 8 | 2.0-7.0 |

| HILIC Plus | 2.2, 3, 5 | 120 | 420 | - | 1.5-7.0 |

| Si | 2.2, 3, 5, 10 | 100 | 420 | - | 1.5-7.0 |

| SAX | 5 | 120 | 325 | - | 1.0-7.5 |

| SCX | 5 | 120 | 325 | - | 1.0-7.5 |

Na našich stránkách naleznete i návod, jak se starat o (U)HPLC kolony Arion.

CHROMSHELL - CHROMSERVIS

| Typ fáze | Velikost částic (µm) | Velikost pórů (Å) | Efektivní plocha povrchu (m2/g) | % uhlíku | Rozsah pH |

|---|---|---|---|---|---|

| CHROMSHELL® C18 Plus | 2.6 | 85 | 130 | 9 | 1.5-7.5 |

| CHROMSHELL® C18-XB | 2.6 | 85 | 130 | 8 | 1.5-8.0 |

| CHROMSHELL® C18 Polar | 2.6 | 85 | 130 | 6.5 | 1.5-7.0 |

KINETEX - PHENOMENEX

| Typ fáze | Velikost částic (µm) | Velikost pórů (Å) | Efektivní plocha povrchu (m2/g) | % uhlíku | Rozsah pH |

|---|---|---|---|---|---|

| Kinetex XB-C18 | 5, 2.6 | 100 | 200 | 10 | 1.5-8.5* |

| Kinetex C18 | 5, 2.6 | 100 | 200 | 12 | 1.5-8.5* |

| Kinetex C8 | 2.6 | 100 | 200 | 8 | 1.5-8.5* |

| Kinetex PFP | 5, 2.6 | 100 | 200 | 9 | 1.5-8.5* |

| Kinetex HILIC | 2.6 | 100 | 200 | 0 | 2.0-7.5 |

| Kinetex Phenyl-Hexyl | 5, 2.6 | 100 | 200 | 11 | 1.5-8.5* |

*Kolony mají stabilitu v rozsahu pH 1.5 až 10 za isokratických podmínek. Při gradientních elucích je jejich stabilita v rozsahu pH 1.5 až 8.5.

Kolony Kinetex 2.6µm s ID 2.1mm jsou stabilní do tlaku 1000 bar, jinak do 600 bar.

Vyzkoušejte kolony ChromShell, kterými kolony Kinetex můžete nahradit.

LUNA - PHENOMENEX

| Typ fáze | Velikost částic (µm) | Velikost pórů(Å) | Plocha povrchu (m2/g) | % uhlíku | Rozsah pH | USP kód |

|---|---|---|---|---|---|---|

| Luna Phenyl-Hexyl | 3,5,10,15 | 100 | 400 | 17.5 | 1.5-10.0 | L11 |

| Luna Silica (2) | 3,5,10,15 | 100 | 400 | - | - | L3 |

| Luna C5 | 5,10 | 100 | 440 | 12.5 | 1.5-10.0 | - |

| Luna C8 | 5,10 | 100 | 440 | 14.75 | 1.5-10.0 | L7 |

| Luna C8 (2) | 3,5,10,15 | 100 | 400 | 13.5 | 1.5-10.0 | L7 |

| Luna C18 | 5,10 | 100 | 440 | 19 | 1.5-10.0 | L1 |

| Luna C18 (2) | 2.5,3,5,10,15 | 100 | 400 | 17.5 | 1.5-10.0 | L1 |

| Luna CN | 3,5,10 | 100 | 400 | 7.0 | 1.5-10.0 | L10 |

| Luna NH2 | 3,5,10 | 100 | 400 | 9.5 | 1.5-11.0 | L8 |

| Luna SCX | 5,10 | 100 | 400 | 0.55% Sulfur Load | 2.0-7.0 | L9 |

| Luna HILIC | 3,5 | 200 | 200 | - | 1.5-8.0 | - |

| Luna PFP(2) | 3 5 | 100 | 400 | 5.7 | 1.5-8.0 | L43 |

GEMINI - PHENOMENEX

| Typ fáze | Velikost částic (µm) | Velikost pórů (Å) | Plocha povrchu (m2/g) | % uhlíku | Rozsah pH | USP kód |

|---|---|---|---|---|---|---|

| Gemini C18 | 3,5,10 | 110 | 375 | 14 | 1.0-12.0 | L1 |

| Gemini C6-Phenyl | 3,5 | 110 | 375 | 12 | 1.0-12.0 | L11 |

| Gemini NX | 3,5,10 | 110 | 375 | 14 | 1.0-12.0 | L1 |

SYNERGI - PHENOMENEX

| Typ fáze | Velikost částic (µm) | Velikost pórů(Å) | Plocha povrchu (m2/g) | % uhlíku | Rozsah pH | USP kód |

|---|---|---|---|---|---|---|

| Synergi Max-RP | 2.5 | 100 | 400 | 17 | 1.5-10.0 | - |

| Synergi Hydro-RP | 2.5 | 100 | 400 | 19 | 1.5-7.5 | L1 |

| Synergi Polar-RP | 2.5 | 100 | 440 | 11 | 1.5-7.0 | L11 |

| Synergi Fusion-RP | 2.5 | 100 | 440 | 12 | 1.5-10.0 | L1 |

| Synergi Max-RP | 4,10 | 80 | 475 | 17 | 1.5-10.0 | - |

| Synergi Hydro-RP | 4,10 | 80 | 475 | 19 | 1.5-7.5 | L1 |

| Synergi Polar-RP | 4,10 | 80 | 475 | 11 | 1.5-7.0 | L11 |

| Synergi Fusion-RP | 4,10 | 80 | 475 | 12 | 1.5-10.0 | L1 |

ONYX - PHENOMENEX

| Typ fáze | Velikost makropórů (µm) | Velikost pórů (Å) | Plocha povrchu (m2/g) | % uhlíku | Rozsah pH | USP kód |

|---|---|---|---|---|---|---|

| Onyx Silica | 2 | 130 | 300 | 0 | 2.0-7.5 | - |

| Onyx C8 | 2 | 130 | 300 | 11 | 2.0-7.5 | - |

| Onyx C18 | 2 | 130 | 300 | 18 | 2.0-7.5 | - |

JUPITER - PHENOMENEX

| Typ fáze | Velikost částic (µm) | Velikost pórů (Å) | Plocha povrchu (m2/g) | % uhlíku | Rozsah pH | USP kód |

|---|---|---|---|---|---|---|

| Jupiter C4 | 5,10,15 | 300 | 170 | 5.0 | 1.5-10.0 | L26 |

| Jupiter C5 | 5,10,15 | 300 | 170 | 5.5 | 1.5-10.0 | - |

| Jupiter C18 | 5,10,15 | 300 | 170 | 13.3 | 1.5-10.0 | L1 |

| Jupiter Proteo C12 | 4,10 | 90 | 475 | 15.0 | 1.5-10.0 | - |

Kapilární / Nano LC kolony ProteCol - SGE

| Typ fáze | Velikost částic(µm) | Velikost pórů (Å) | Plocha povrchu (m2/g) | % uhlíku | Rozsah pH | USP kód |

|---|---|---|---|---|---|---|

| ProteCol C18 | 3 | 120/300 | 350 | 17 | 2.0-7.5 | L1 |

| ProteCol C8 | 3 | 120/300 | 350 | 10 | 2.0-7.5 | L7 |

| ProteCol C4 | 3 | 120/300 | 350 | 2.0-7.5 | L26 | |

| ProteCol SCX | 3 | 120/300 | 350 | 2.0-7.5 | L9 |

Přehled sorbentů MSPE

Sorbenty pro techniku MSPE jsou zvoleny tak, aby pokryly co nejširší pole aplikací. MSPE SpeExtra C18 je hydrofóbní typ oktadecyl silikagelu se speciálním endcappingem s velmi širokým uplatněním. Je vhodný pro celou řadu analytů, horší retenci vykazuje pro polární sloučeniny. MSPE SpeExtra C18-P je polárně modifikovaný monomerní oktadecyl silikagel . Nabízí různé typy interakcí: dipól-dipól, π- π a hydrofóbní. Je tedy vhodný pro aromatické a polární sloučeniny. MSPE SpeExtra HLB polymerní sorbent s vysokým měrným povrchem a speciálním endcappingem. Má hydrofilní a lipofilní modifikaci zajišťující univerzální použití a vyšší kapacitu než C18 silikagel. MSPE SpeExtra WAX je polymerní sorbent na bázi PS/DVB se speciálním end-cappingem a vysoce specifickým povrchem, který se připravuje kopolymerací styrenu a divinylbenzenu, přičemž vytváří slabé aniontové interakce.

| MSPE sorbent | Velikost částic [µm] | Měrný povrch [m2/g] |

| C18 | 60 | 310 |

| C18-P | 60 | 310 |

| HLB | 30 | 850 |

| WAX | 30 | 850 |

Fáze pro SPE

Na této stránce uvádíme přehled nabízených kolonek pro extrakci na pevné fázi (SPE) včetně technických parametrů. Další informace k produktům najdete v katalogu zboží, ve kterém jsou uvedeny SPE kolonky a disky, dSPE produkty, manifoldy, produkty pro on-line SPE a vakuová čerpadla.

Clean up SPE kolonky

Reverzní fáze hydrofobní

| Phase | Particle size (µm) | Pore Size (A) | Surface Area (m2/g) | Carbon Load (%) | End Capping | Feature |

|---|---|---|---|---|---|---|

| C2 Ethyl | 60 | 500 | 6,6 | YES/NO | ||

| C4 n-Butyl | 60 | 500 | 8,5 | YES | ||

| C8 Octyl | 60 | 500 | 11,1 | YES/NO | ||

| C18 Octadecyl | 60 | 500 | 21,7 | YES/NO | ||

| C30 Tricontyl | 60 | 500 | 20,0 | YES | ||

| Cyclohexyl | 60 | 500 | 11,6 | YES/NO | ||

| Phenyl | 60 | 500 | 11,0 | YES/NO |

Normální fáze hydrofilní

| Phase | Particle size (µm) | Pore Size (A) | Surface Area (m2/g) | Carbon Load (%) | Feature | |

|---|---|---|---|---|---|---|

| Silica | 0,77 | 60 | 500 | N/A | ||

| Diol | 0,77 | 60 | 500 | 8,0 | ||

| Cyanopropyl | 0,77 | 60 | 500 | 9,0 | ||

| Florisil | 0,82 | 60 | 500 | N/A | ||

| Alumina, Acidic | 60 | 500 | N/A | |||

| Alumina, Basic | 60 | 500 | N/A | |||

| Alumina, Neutral | 60 | 500 | N/A | |||

| Carbon | N/A | 120/140 mesh |

Ion Anion Exchange fáze

| Phase | Pore volume (cm3/g) | pKa | Pore Size (A) | Surface Area (m2/g) | Carbon Load (%) | Exchange (meq/g) |

|---|---|---|---|---|---|---|

| Aminopropyl (1 amine) | 0,77 | 9.8 | 60 | 500 | 6,65 | 0,31 |

| N-2 Aminoethyl (1/2 amine) | 0,77 | 10.1; 10.9 | 60 | 500 | 11,1 | 0,32 |

| Diethylamino (3 amine) | 0,77 | 10.6 | 60 | 500 | 10,6 | 0,28 |

| Quarternary Amine Chloride | 0.77 | Always charged | 60 | 500 | 8,4 | 0,25 |

| Quarternary Amine Hydroxide | 0.77 | Always charged | 60 | 500 | 8,4 | 0,25 |

| Quarternary Amine Acetate | 0.77 | Always charged | 60 | 500 | 8,4 | 0,25 |

| Quarternary Amine Formate | 0.77 | Always charged | 60 | 500 | 8,4 | 0,25 |

| Polyimine | 0,77 | Always charged | 13,5 | 0,25 |

Ion Cation Exchange fáze

| Phase | Pore volume (cm3/g) | pKa | Pore Size (A) | Surface Area (m2/g) | Carbon Load (%) | Exchange (meq/g) |

|---|---|---|---|---|---|---|

| Carboxylic Acid | 0.77 | 4.8 | 60 | 500 | 9,2 | 0,17 |

| Propylsulfonic Acid | 0.77 | 1 | 60 | 500 | 7,1 | 0,18 |

| Benzenesulfonic Acid | 0.77 | Always charged | 60 | 500 | 11,0 | 0,32 |

| Benzenesulfonic Acid, High Load | 0.77 | Always charged | 60 | 500 | 15,0 | 0,65 |

| Triacetic Acid | 0,77 | 60 | 500 | 7,61 | Anion 0,17/Cation 0,06 |

Kopolymerní fáze

| Phase | Pore volume (cm3/g) | pKa | Pore Size (A) | Surface Area (m2/g) | Carbon Load (%) | Exchange (meq/g) |

|---|---|---|---|---|---|---|

| Aminopropyl + C8 | 0.77 | 9,8 | 60 | 500 | 12,3 | 0,163 |

| Quarternary Amine + C8 | 0.77 | Always charged | 60 | 500 | 13,6 | 0,160 |

| Carboxylic Acid + C8 | 0.77 | 4,8 | 60 | 500 | 2,5 | 0,105 |

| Propylsulfonic Acid + C8 | 0.77 | 1 | 60 | 500 | 14,62 | 0,114 |

| Benzenesulfonic Acid + C8 | 0,77 | Always charged | 60 | 500 | 12.3 | 0,072 |

| Cyanopropyl + C8 | 0,77 | N/A | 60 | 500 | 14,6 | 0,163 |

| Cyclohexyl + C8 | 0.77 | N/A | 60 | 500 | N/A | N/A |

Stacionární fáze pro GC

Na této stránce uvádíme přehled dodávaných stacionárních fází pro plynovou chromatografii (GC). U každé jsou uvedeny podrobné údaje o jejích vlastnostech a aplikacích, které jsou pro ně vhodné. V katalogu produktů si pak můžete vybrat vhodnou křemennou či kovovou kapilární kolonu pro GC.

Stacionární fáze LION

Křemenné kapilární kolony

| Stacionární fáze | Teplotní limity | Chemické složení | USP kód |

|---|---|---|---|

| LN-1 | -60 až 370°C | 100% dimetyl polysiloxan | G2 |

| LN-1 MS | -60 až 370°C | 100% dimetyl polysiloxan | G2 |

| LN-1 HT | -60 až 430°C | 100% dimetyl polysiloxan | - |

| LN-5 | -60 až 370°C | 5% difenyl/95% dimetyl polysiloxan | G27 |

| LN-5 Sil MS | -60 až 370°C | 5% difenyl/95% dimetyl polysiloxan | G27 |

| LN-5 MS | -60 až 350°C | 5% fenyl - arylen - 95% dimetyl polysiloxan | G27 |

| LN-5 HT | -60 až 430°C | 5% difenyl/95% dimetyl polysiloxan | - |

| LN-35 | 50 až 360°C | 35% difenyl/65% dimetyl polysiloxan | G42 |

| LN-35 HT | -60 až 400°C | 35% difenyl/65% dimetyl polysiloxan | G42 |

| LN-17 MS | 40 až 340°C | 50% dipenyl/50% dimetyl polysiloxan | G3 |

| LN-624 | -20 až 260°C | 6% kyanopropylfenyl/94% dimetyl polysiloxan | G43 |

| LN-FFAP | 40 až 260°C | Polyetylén glykol modifikovaný kyselinou nitrotereftalovou | G35 |

| LN-1701 | -20 až 300°C | 14% kyanopropylfenyl/86% dimetyl polysiloxan | G46 |

| LN-XLB | 30 až 360°C | Fáze s nízkou polaritou | - |

| LN-XLB-HT | 30 až 400°C | Fáze s nízkou polaritou | - |

| LN-WAX | 40 až 260°C | Polyetylen glykol | G16 |

| LN-WAX Plus | 20 až 260°C | Polyetylen glykol | G16 |

Stacionární fáze Restek

Křemenné kapilární kolony

| Stacionární fáze | Teplotní limity | Chemické složení | USP kód |

|---|---|---|---|

| Rxi®-1MS | -60 až 350°C | 100% dimetyl polysiloxan | G2 |

| Rxi®-1HT | -60 až 400°C | 100% dimetyl polysiloxan | |

| Rxi®-5MS | -60 až 350°C | 5% difenyl/95% dimetyl polysiloxan | G27 |

| Rxi®-5Sil MS | -60 až 350°C | silarylenová fáze (selektivita jako 5% fenyl 95%dimetyl polysiloxan) | - |

| Rxi®-5HT | -60 až 400°C | 5% difenyl/95% dimetyl polysiloxan | - |

| Rxi®-XLB | 30 až 360°C | fáze s nízkou polaritou | - |

| Rxi®-35Sil MS | 50 až 360°C | aplikačně specifická fáze (selektivita jako 35% difenyl/65% dimetyl polysiloxan) | - |

| Rxi®-624Sil MS | -60 až 320°C | silarylenová fáze (selektivita jako 6% kyanopropylfenyl/94% dimetyl polysiloxan) | - |

| Rxi®-17 | 40 až 320°C | 50% difenyl/50% dimetyl polysiloxan | - |

| Rxi®-17Sil MS | 40 až 360°C | silarylenová fáze (selektivita jako 100% fenylmetyl polysiloxan) | G3 |

| Rtx®-1 | -60 až 350°C | 100% dimetyl polysiloxan | G1,G2,G38 |

| Rtx®-1 F&F | -60 až 350°C | 100% dimetyl polysiloxan (optimalizovaný) | - |

| Rtx®-1PONA | -60 až 340°C | 100% dimetyl polysiloxan (optimalizovaný) | - |

| Rtx®-2887 | -60 až 360°C | 100% dimetyl polysiloxan (optimalizovaný) | - |

| Rtx®-5 | -60 až 350°C | 5% difenyl/95% dimetyl polysiloxan | G27,G36 |

| Rtx®-5 Amine | -60 až 315°C | 5% difenyl/95% dimetyl polysiloxan (optimalizovaný) | - |

| Rtx®-5 PONA | 60 až 325°C | 5% difenyl/95% dimetyl polysiloxan (optimalizovaný) | - |

| Rtx®-1301 | -20 až 280°C | 6% kyanopropylfenyl/94% dimetyl polysiloxan | G43 |

| Rtx®-624 | -20 až 240°C | 6% kyanopropylfenyl/94% dimetyl polysiloxan | G43 |

| Rtx®-20 | -20 až 320°C | 20% difenyl/80% dimetyl polysiloxan | G28,G32 |

| Rtx®-35 | 40 až 320°C | 35% difenyl/65% dimetyl polysiloxan | G42 |

| Rtx®-35 MS | 40 až 320°C | 35% difenyl/65% dimetyl polysiloxan (optimalizovaný) | G42 |

| Rtx®-35 Amine | 40 až 320°C | 35% difenyl/65% dimetyl polysiloxan (optimalizovaný) | G42 |

| Rtx®-1701 | -20 až 280°C | 14% kyanopropylfenyl/86% dimetyl polysiloxan | G46 |

| Rtx®-200 | -20 až 340°C | Trifluoropropylmetyl polysiloxan | G6 |

| Rtx®-200MS | -20 až 340°C | Trifluoropropylmetyl polysiloxan | G6 |

| Rtx®-50 | 40 až 320°C | 100% metylfenyl polysiloxan | G3 |

| Rtx®-65 | 50 až 300°C | 65% difenyl/35% dimetyl polysiloxan | G17 |

| Rtx®-65TG | 40 až 370°C | 65% difenyl/35% dimetyl polysiloxan (optimalizovaný) | - |

| Rtx®-225 | 40 až 240°C | 50% kyanopropylmetyl/50% fenylmetyl polysiloxan | G7,G19 |

| Rtx®-440 | 20 až 340°C | Středně polární fáze | - |

| Rtx®-Wax | 20 až 250°C | Carbowax® polyetylen glykol | G14,G15,G16 |

| Stabilwax® | 40 až 250°C | Carbowax® polyetylen glykol | G14,G15,G16 |

| Stabilwax®-DB | 40 až 250°C | Carbowax® polyetylen glykol | - |

| Stabilwax®-DA | 40 až 250°C | Carbowax® polyetylen glykol | G25,G35 |

| FAMEWAX | 20 až 250°C | Polyetylen glykol | - |

| Rt™-CW20M F&F | 60 až 220°C | Carbowax® polyetylen glykol | - |

| Rt™-2330 | 0 až 275°C | Biskyanopropyl polysiloxan | G48 |

| Rt™-2560 | 20 až 250°C | 90% biskyanopropyl/10% fenylkyanopropyl polysiloxan | - |

| Stx™-500 | -60 až 380°C | Karboran/dimetyl polysiloxan | - |

| Rtx®-VMS | -40 až 260°C | Aplikačně specifická fáze | - |

| Rtx®-502.2 | -20 až 270°C | Aplikačně specifická fáze | - |

| Rtx®-VRX | -40 až 260°C | Aplikačně specifická fáze | - |

| Rtx®-VGC | -40 až 260°C | Aplikačně specifická fáze | - |

| Rtx®-Volatiles | -20 až 280°C | Aplikačně specifická fáze | - |

| Rtx®-CLPesticides | -60 až 340°C | Aplikačně specifická fáze | - |

| Rtx®-CLPesticides2 | -60 až 340°C | Aplikačně specifická fáze | - |

| Stx™-CLPesticides | -60 až 330°C | Aplikačně specifická fáze | - |

| Stx™-CLPesticides2 | -60 až 330°C | Aplikačně specifická fáze | - |

| Rtx®-OPPesticides | -20 až 330°C | Aplikačně specifická fáze | - |

| Rtx®-OPPesticides2 | -20 až 330°C | Aplikačně specifická fáze | - |

| Rtx®-Dioxin | -60 až 380°C | Aplikačně specifická fáze | - |

| Rtx®-Dioxin2 | 20 až 340°C | Aplikačně specifická fáze | - |

| Rtx®-PCB | 30 až 340°C | Aplikačně specifická fáze | - |

| Rtx®-1614 | -60 až 360°C | Aplikačně specifická fáze | - |

| Rt™-PAH | 80 až 285°C | Fáze z tekutých krystalů | - |

| Rtx®-TNT | -20 až 310°C | Aplikačně specifická fáze | - |

| Rtx®-TNT 2 | -20 až 310°C | Aplikačně specifická fáze | - |

| Rtx®-Biodiesel TG | do 380°C | Aplikačně specifická fáze | - |

| Rt™-TCEP | 0 až 135°C | 1,2,3-tris[2-kyanoetoxy]propan | - |

| Rtx®-BAC1 | -20 až 260°C | Aplikačně specifická fáze | - |

| Rtx®-BAC2 | -20 až 260°C | Aplikačně specifická fáze | - |

| Rt™-ßDEXcst | 40 až 230°C | Chirální fáze | - |

| Rt™-ßDEXm | 40 až 230°C | Chirální fáze | - |

| Rt™-ßDEXsa | 40 až 230°C | Chirální fáze | - |

| Rt™-ßDEXse | 40 až 230°C | Chirální fáze | - |

| Rt™-ßDEXsm | 40 až 230°C | Chirální fáze | - |

| Rt™-ßDEXsp | 40 až 230°C | Chirální fáze | - |

| Rt™-yDEXsa | 40 až 230°C | Chirální fáze | - |

Kovové kapilární kolony

| Stacionární fáze | Teplotní limity | Chemické složení | USP kód |

|---|---|---|---|

| MXT®-1 | -60 až 430°C | 100% dimetyl polysiloxan | G1,G2,G38 |

| MXT®-1HT SimDist | -60 až 430°C | Aplikačně specifická fáze | - |

| MXT®-1 SimDist | -60 až 430°C | Aplikačně specifická fáze | - |

| MXT®-2887 | -60 až 400°C | Aplikačně specifická fáze | - |

| MXT®-5 | -60 až 430°C | 5% difenyl/95% dimetyl polysiloxan | G27,G36 |

| MXT®-20 | -20 až 320°C | 20% difenyl/80% dimetyl polysiloxan | G28,G32 |

| MXT®-35 | 0 až 310°C | 35% difenyl/65% dimetyl polysiloxan | G42 |

| MXT®-50 | 0 až 290°C | 100% metylfenyl polysiloxan | G3 |

| MXT®-65 | 50 až 300°C | 65% difenyl/35% dimetyl polysiloxan | G17 |

| MXT®-65TG | 20 až 370°C | 65% difenyl/35% dimetyl polysiloxan (optimalizovaný) | - |

| MXT®-624 | -20 až 240°C | 6% kyanopropylfenyl/94% dimetyl polysiloxan | G43 |

| MXT®-1301 | -20 až 280°C | 6% kyanopropylfenyl/94% dimetyl polysiloxan | G43 |

| MXT®-1701 | -20 až 280°C | 14% kyanopropylfenyl/86% dimetyl polysiloxan | G46 |

| MXT®-200 | -20 až 400°C | Trifluoropropylmetyl polysiloxan | G6 |

| MXT®-WAX | 40 až 260°C | Carbowax® polyetylen glykol | G14,G15,G16 |

| MXT®-500 SimDist | -60 až 430°C | Karboran-siloxanový polymer | - |

| MXT®-502.2 | -20 až 270°C | Aplikačně specifická fáze | - |

| MXT®-Biodiesel TG | -60 až 430°C | Aplikačně specifická fáze | - |

| MXT®-Volatiles | -20 až 280°C | Aplikačně specifická fáze | - |

PLOT kolony

| Stacionárne fázy | Teplotné limity | Chemické zloženie | USP kód |

|---|---|---|---|

| Rt®-Alumina BOND | do 200°C | Al2O3 (Na2SO4 deaktivace) | - |

| Rt®-Alumina BOND | do 200°C | Al2O3 (KCl deaktivace) | |

| Rt®-Msieve 13X | do 300°C | Molekulové síto 13X | - |

| Rt®-Msieve 5A | do 300°C | Molekulové síto 5A | - |

| Rt®-Q-BOND | do 320°C | 100% divinylbenzen | - |

| Rt®-QS-BOND | do 250°C | Porézny divinylbenzen homopolymer | - |

| Rt®-S-BOND | do 250°C | Divinylbenzen 4-vinylpyridin | - |

| Rt®-U-BOND | do 190°C | Divinylbenzen etylenglykol/dimetylakrylát | - |

Kovové plot kolony

| Stacionární fáze | Teplotní limit | Chemické složení | USP kód |

|---|---|---|---|

| Mtx®-Alumina Bond | až 200°C | Al2O3 (Na2SO4 deaktivace) | - |

| Mtx®-MSieve 5A | až 300°C | Molekulové síto 5A | - |

Stacionární fáze SGE

Křemenné kapilární kolony

| Stacionární fáze | Teplotní limity | Chemické složení | USP kód |

|---|---|---|---|

| forte BP1 | -60 až 360°C | 100% dimetyl polysiloxan | G1,G2,G38 |

| forte SolGel 1MS | 0 až 380°C | 100% dimetyl polysiloxan | G1,G2,G38 |

| forte BPX1 | -30 až 430°C | 100% dimetyl polysiloxan (optimalizovaný) | - |

| forte BP1 PONA | -60 až 360°C | 100% dimetyl polysiloxan (optimalizovaný) | - |

| forte BP5 | -60 až 360°C | 5% fenyl metyl polysiloxane | G28,G32 |

| forte BPX5 | -40 až 370°C | 5% fenyl polysilfenylene siloxan | - |

| forte HT5 | 10 až 400°C | 5% fenyl polykarboran siloxan | - |

| forte HT8 | -20 až 370°C | 8% fenyl polykarboran siloxan | - |

| forte BPX35 | 0 až 370°C | 35% fenyl polysilfenylen siloxan | G42 |

Stacionární fáze pro UHPLC

Raptor - RESTEK

| Typ fáze | Velikost částic (µm) | Velikost pórů (Å) | Efektivní plocha povrchu (m2/g) | Obsah uhlíku (%) | Rozsah pH |

|---|---|---|---|---|---|

| Raptor ARC-C18 | 1.8 | 90 | 125 | neveřejné | 1.0-8.0 |

| Raptor ARC-C18 | 2.7 | 90 | 130 | neveřejné | 1.0-8.0 |

| Raptor ARC-C18 | 5.0 | 90 | 100 | neveřejné | 1.0-8.0 |

| Raptor C18 | 1.8 | 90 | 125 | neveřejné | 2.0-8.0 |

| Raptor C18 | 2.7 | 90 | 130 | neveřejné | 2.0-8.0 |

| Raptor C18 | 5.0 | 90 | 100 | neveřejné | 2.0-8.0 |

| Raptor Biphenyl | 1.8 | 90 | 125 | neveřejné | 1.5-8.0 |

| Raptor Biphenyl | 2.7 | 90 | 130 | neveřejné | 1.5-8.0 |

| Raptor Biphenyl | 5.0 | 90 | 100 | neveřejné | 1.5-8.0 |

| Raptor Fluorophenyl | 1.8 | 90 | 125 | neveřejné | 2.0-8.0 |

| Raptor Fluorophenyl | 2.7 | 90 | 130 | neveřejné | 2.0-8.0 |

| Raptor Fluorophenyl | 5.0 | 90 | 100 | neveřejné | 2.0-8.0 |

| Raptor HILIC-Si | 2.7 | 90 | 150 | n/a | 2.0-8.0 |

| Raptor EtG/EtS | 2.7 | 90 | 130 | neveřejné | 2.0-8.0 |

Maximální tlak kolon Raptor je: 1,034 bar (1.8 μm), 600 bar (2.7 μm); 400 bar (5 μm). Pro delší životnost doporučujeme tlak pro kolony 1.8 µm maximálně 830 bar.

PINNACLE DB - RESTEK

| Typ fáze | Velikost částic(µm) | Velikost pórů (Å) | Plocha povrchu (m2/g) | Obsah uhlíku (%) | Rozsah pH |

|---|---|---|---|---|---|

| Pinnacle DB C18 | 1.9 | 140 | 150 | 11 | 2.5-8.0 |

| Pinnacle DB Aqueous C18 | 1.9 | 140 | 150 | 6 | 2.5-8.0 |

| Pinnacle DB C8 | 1.9 | 140 | 150 | 6 | 2.5-8.0 |

| Pinnacle DB CN | 1.9 | 140 | 150 | 4 | 2.5-8.0 |

| Pinnacle DB PFP | 1.9 | 140 | 150 | 6 | 2.5-8.0 |

| Pinnacle DB Biphenyl | 1.9 | 140 | 150 | 8 | 2.5-8.0 |

| Pinnacle DB IBD | 1.9 | 140 | 150 | neveřejné | 2.5-8.0 |

| Pinnacle DB Silica | 1.9 | 140 | 150 | n/a | 2.5-8.0 |

dSPE (QuEChERS)

Produkty Resprep™ QuEChERS

Extrakční a Clean-Up dSPE zkumavky QuEChERS pro reziduální analýzu pesticidů v potravinách

- Rychlá, jednoduchá extrakce a přečištění vzorku s použitím dSPE zkumavek.

- Čtyřnásobné zvýšení výkonosti předúpravy vzorků.

- Čtyřnásobné snížení nákladů na předúpravu vzorků.

- Praktické centrifugační zkumavky s vysocečistými předváženými směsmi adsorbentů.

Metoda QuEChERS ("catchers")- Quick, Easy, Cheap, Effective, Rugged, and Safe - byla vyvinuta a publikována institutem US Department of Agriculture Eastern Regional Research Center ve Wyndmooru, PA.(1) Vědečtí pracovníci hledali jednoduchou, efektivní a levnou cestu pro extrakci a přečištění vzorků pro reziduální analýzu pesticidů s cílem nahradit modifikované extrakční metody, které jsou vysoce účinné a robustní, ale také naročné na vybavení laboratoře a tedy i drahé. Extrakce na tuhou fázi (SPE) je také účinná metoda, ale v případě komplexních matric je nutné použít více jednotlivých kolonek s různými sorbenty pro odstranění mnoha skupin interferujících látek. Nová metoda QuEChERS odstraňuje sacharidy, lipidy, organické kyseliny, steroly, proteiny, barviva a vodu. Je jednoduchá a levná.

Metoda QuEChERS ("catchers")- Quick, Easy, Cheap, Effective, Rugged, and Safe - byla vyvinuta a publikována institutem US Department of Agriculture Eastern Regional Research Center ve Wyndmooru, PA.(1) Vědečtí pracovníci hledali jednoduchou, efektivní a levnou cestu pro extrakci a přečištění vzorků pro reziduální analýzu pesticidů s cílem nahradit modifikované extrakční metody, které jsou vysoce účinné a robustní, ale také naročné na vybavení laboratoře a tedy i drahé. Extrakce na tuhou fázi (SPE) je také účinná metoda, ale v případě komplexních matric je nutné použít více jednotlivých kolonek s různými sorbenty pro odstranění mnoha skupin interferujících látek. Nová metoda QuEChERS odstraňuje sacharidy, lipidy, organické kyseliny, steroly, proteiny, barviva a vodu. Je jednoduchá a levná.

Tým vědců vyvinul jednoduchou medodu, skládající se ze dvou kroků. První krok procedury je extrakce zhomogenizovaného vzorku a frakcionace pomocí organického rozpouštědla a roztoků solí. Druhý krok je extrakce a přečištění organické vrstvy s pomocí dispersivní SPE techniky. Ke směsi adsorbentů je přidán 1 ml organického rozpouštědla z kroku 1, obsah je důkladně promíchán a zcentrifugován. Nyní je připraven čistý extrakt pro analýzu různými GC a HPLC technikami. (2) Validační data metody QuEChERS jsou k dispozici pro širokou škálu pesticidů v několika běžných potravinách na www.quechers.com.

Použitá dispersivní SPE metoda, množství a typy adsorbentů, pH nebo polarita rozpouštědel může být jednoduše optimalizována pro různé matrice a analyty. Výsledky tohoto postupu jsou ověřovány a kvalifikovány několika USDA (US Dep. of Agriculture) a administrativními potravinářskými laboratořemi a jsou tak plně akceptovány pro mnoho matric reziduální analýzy pesticidů.

Produkty Resprep™ ještě více tento postup zjednodušují. Cetrifugační zkumavky, dostupné v rozměrech 2 a 15 ml, obsahují síran hořečnatý (odstranění vody z organické frakce) a PSA* adsorbent (odstranění sacharidů a mastných kyselin), dále mohou být s přídavkem grafitizovaného uhlíku (odstranění pigmentů a sterolů) nebo adsorbentu C18 (odstranění nepolárních interferujících látek).

Pokud jste nespokojení s časem a výší finančních nákladů vynaložených na předúpravu vzorků pro reziduální analýzu pesticidů, vyzkoušejte tuto novou jednoduchou a ekonomickou metodu.

Více informací o jednotlivých produktech naleznete zde.

Reference:

- Anastassiades, M., S.J. Lehotay, D. Stajnbaher, F.J. Schenck, Fast and Easy Multiresidue Method Employing Acetonitrile Extraction/Partitioning and "Dispersive Solid-Phase Extraction" for the Determination of Pesticide Residues in Produce, J AOAC International, 2003, vol 86 no 22, pp 412-431.

- Schenck, F.J., SPE Cleanup and the Analysis of PPB Levels of Pesticides in Fruits and Vegetables. Florida Pesticide Residue Workshop, 2002

Fáze MEPS

Jehly BIN se dodávají s různými SPE fázemi. Rozměry lože sorbentu zajišťují, že separační schopnost sorbentu je identická s konvenční SPE. Příprava vzorků komplexních biologických matric je pomocí MEPS jednoduchá a snižuje nároky na objem vzorku a používaných reagencií ve srovnání se SPE nebo jinými „mikroextrakčními technikami“. MEPS využívá separaci pomocí reverzní fáze, normální fáze, směsného módu a iontové výměny. Jelikož MEPS umožňuje práci s malými objemy (až 10µL), je vhodnou technikou pro přímé propojení s LC-MS systémy. Současný rozsah stříkaček umožňuje ruční použití nebo využití automatických dávkovačů Thermo Scientific, CTC Analytics, HTA 300APlus a Varian 8400 bez nutnosti jejich úpravy. Jehly BIN jsou v provedení pro LC a GC aplikace. Jehly jsou baleny v utěsněných fóliích po 5 kusech.

SGE

| Fáze | Velikost částic (µm) | Velikost pórů (A) |

|---|---|---|

| Silikagel | 45 | 60 |

| C2 | 45 | 60 |

| C8 | 45 | 60 |

| C8+SCX* | 45 | 60 |

| C18 | 45 | 60 |

*C8+SCX jehly BIN jsou označeny jako M1.

Jehly BIN lze zpravidla použít pro 40 - 100 extrakcí. Obvyklá doba přípravy vzorku je 1 - 2 minuty.

Stacionární fáze

GC, HPLC, SPE, FLASH- nebo preparativní chromatografie používají širokou řadu stacionárních fází. Na těchto stránkách naleznete bližší informace o jednotlivých typech.

GC, HPLC, SPE, FLASH- nebo preparativní chromatografie používají širokou řadu stacionárních fází. Na těchto stránkách naleznete bližší informace o jednotlivých typech.

Stacionární fáze pro analytické separace

Stacionární fáze pro přípravu vzorků

- SPE

- dSPE (QuEChERS)

- IAC (imunoafinitní kolonky)

- MEPS (mikroextracke na pevné fázi)

- FLASH

- BULK (média pro preparativní chromatografii)

Kovové ferulky SilTite pro GC a GC/MS

Ferulky SilTite jsou unikátní kovové ferulky designované pro spojení křemenných kapilárních GC kolon a kapilár s hmotnostními spektrometry a GC injektory. Již po prvním správném utažení poskytují ferulky SilTite těsné spojení i po mnoha teplotních cyklech bez nutnosti dalšího datahování. Ferulky SilTite se používají ve spojení s maticemi a fitinkam SGE SilTite s katalogovými čísly:

Ferulky SilTite jsou unikátní kovové ferulky designované pro spojení křemenných kapilárních GC kolon a kapilár s hmotnostními spektrometry a GC injektory. Již po prvním správném utažení poskytují ferulky SilTite těsné spojení i po mnoha teplotních cyklech bez nutnosti dalšího datahování. Ferulky SilTite se používají ve spojení s maticemi a fitinkam SGE SilTite s katalogovými čísly:

- SGE*073200

- SGE*073201

- SGE*073202

- SGE*073203

Proč volit ferulky SilTite?

- eliminace netěsností (viz obrázky níže)

- není nutné další dotahování, a to dokonce po více teplotních cyklech

- ferulky zůstávají trvale fixovány na koloně a nepřilnou k matici

- žádná kontaminace z materiálu Vespel nebo grafit - 100% kov

- ideální pro vysokotlaké aplikace (fast GC)

- vhodné pro připojení k injektorům

- maximální teplota >500°C

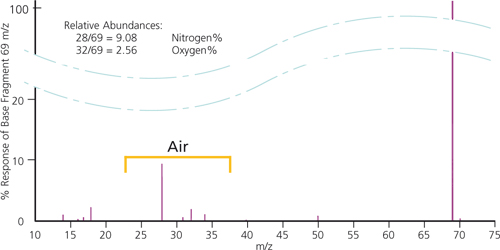

Obu 1. Stopy vzduchu v MS systému po 5 teplotních cyklech při použití ferulek Vespel/grafit.

Obr 2. MS spektrum po 5 teplotních cyklech při použití ferulek Siltite. (U MS, nejsou přítomny netěsnosti dokonce i po 400 teplotních cyklech 70ºC a 400ºC).

Vylepšení těsnění u injektorů GC Agilent

Těsnění injektoru GC Agelint nevyžadující podložku má výrazně vyšší těsnost než originální díl výrobce a je sním mnohem jednodušší manipulace.

Těsnění injektoru GC Agelint nevyžadující podložku má výrazně vyšší těsnost než originální díl výrobce a je sním mnohem jednodušší manipulace.

- zabraňuje permeaci kyslíku do nosného plynu a tím prodlužuje životnost kolony

- o-kroužek (Vespel®) na okraji disku výrazně usnadňuje utahování a nevyžaduje použití velké síly

- o-kroužek (Vespel®) na spodní části disku eliminuje nutnost použití podložky (jednodušší instalace).

Split/splitless injektor v plynových chromatografech Agilent obsahuje ve spodní části kovové těsnění, které se obtížně vyměňuje a nevykazuje dokonalou těsnost (spojení kov-kov). I při dotažení velkou silou vykazuje spojení kov-kov poměrně velké netěsnosti, obzvláště pak, použije-li se těsnění opakovaně. To má za následek pronikání atmosférického kyslíku do nosného plynu a pozvolnou degradaci stacionární fáze instalované GC kolony.

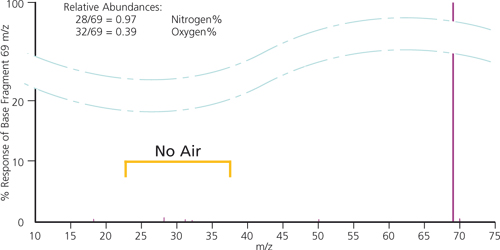

Porovnání těsnosti originálního těsnění Agilent s těsněním Restek

Patentované těsnění Dual Vespel® Ring Inlet Seal (Restek) výrazně zvyšuje těsnost injektoru i po opakovaných teplotních cyklech bez nutnosti opětovného dotahování matice. Těsnění zajišťují dva o-kroužky z materiálu Vespel® – jeden je umístěný na horní straně disku, druhý na jeho spodní části. Tyto o-kroužky eliminují nutnost použití podložky a usnadňují dotahování matice, která disk drží (nyní nutná velká síla pro její dotažení). Testy těsnosti na únik helia prokázali dokonakou těsnost i při lehkém dotažení těsnění.

Varianty těsnění

- nerezové

- pozlacené

- s deaktivací Siltek