Flash and Preparative HPLC

EasyFlash columns

Chromservis has launched new EasyFlash columns for high efficient flash chromatography. In this article, you will learn about the Flash chromatography benefits.

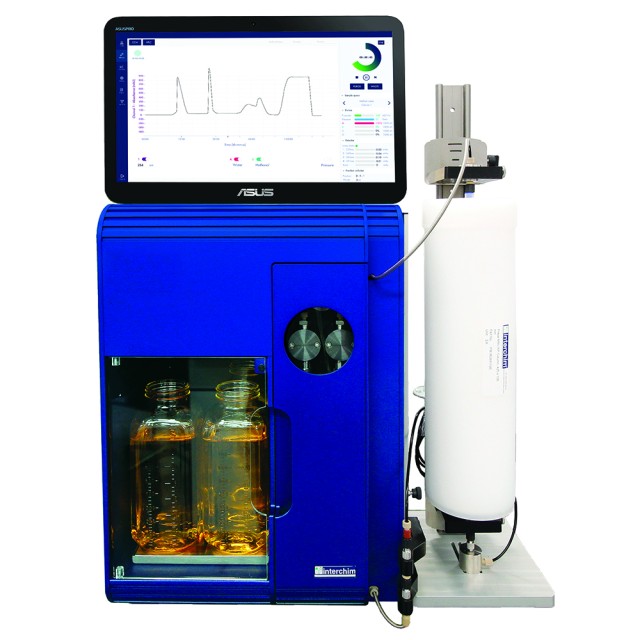

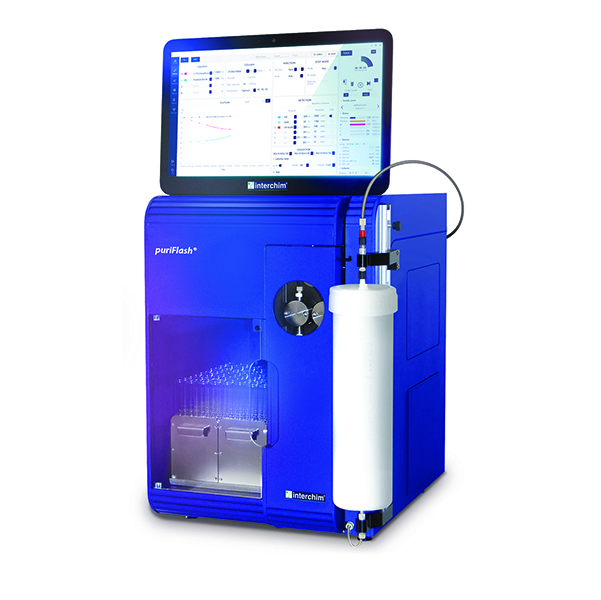

puriFlash

puriFlash® Flash Cartridges

Interchim developed new technique for flash chromatography - Ultra Performance Flash Purification (UPFP) using special flash cartridges. The flash cartridges are in the form of regular or irregular silica. UPFP enables to run purifications with high purity of the yield and less solvent use.

Preparative LC

Task for preparative HPLC systems differs to analytical one. While analytical HPLC task is qualitative and quantitative determination of defined compounds in samples, preparative HPLC task is separation, purification and isolation of value products from mixtures.

Task for preparative HPLC systems differs to analytical one. While analytical HPLC task is qualitative and quantitative determination of defined compounds in samples, preparative HPLC task is separation, purification and isolation of value products from mixtures.

Preparative chromatography can be devidet into three main areas:

- Semi-preparative separations

- Batch preparative chromatography (pilot or industrial scale)

- True Counter-current chromatography

- Simulated moving bed (SMB)

- Continuous chromatography

Scale definition

| Parameter | Analytical | Semi-preparative | Preparative |

|---|---|---|---|

| Column sizes (mm) | 120 - 250 x 2 - 4.6 | 120 - 250 x 8 - 16 | 120 - 250 x 20 - 62 |

| Particle size (µm) | up to 5 | 5 - 10 | higher than 10 |

| Stationary phase (g) | up to 5 | 5 - 30 | 50 - 450 |

| Tubings | 1/16" | 1/16" | 1/8" |

| Flow rates (ml/min) | 0.1 - 2 | 5 - 50 | 100 - 1000 |

| Sample size (mg) | 0.01 - 2 | 0.1 - 50 | 1 - 700 |

| Flow cell (mm) | 10 | 3 | 0.5 - 2 |

Preparative chromatography can be conbined with Flash chromatography in one system - purification device. The PuriFlash (Advion-Interchim) offers different modes of operation:

- Preparative line + Flash line

- Two Flash lines

- Two Preparative lines.

Sample loading in Flash chromatography

Liquid or solid, with small or large sample volumes: because your challenges are just as varied as your injections, we offer multiple possibilities for optimisation, to guarantee you the best results day after day.

Dry Load & Accessories

So far only available in a disposable plastic version, the Dry Loads are now also available in a stainless steel version. These are reusable and also have the advantage of greater resistance to pressure.

With the stainless steel Dry Loads, you can carry out solid injections on a preparative column and in flash column applications where the maximum pressure resistance of a plastic Dry Load would be insufficient.

Injection loops

Thanks to our range covering volumes from 100 μl to 50 mL, there is always an injection loop suited to your needs.

Autosampler

Autosampler

Automate your injections with our autosampler and increase your performance tenfold. The puriFlash® AS-1 allows the injection of samples from 500 µl to 500 mL, with an automated cleaning of the transfer tubes between each injection. The injection is managed by a sample queue on InterSoft software. The autosampler xan be equiped with 6-way or 10-way electric valve.

One rack/slot offers capacities fo the test tubes/bottles up to 250 mL and custom racks.

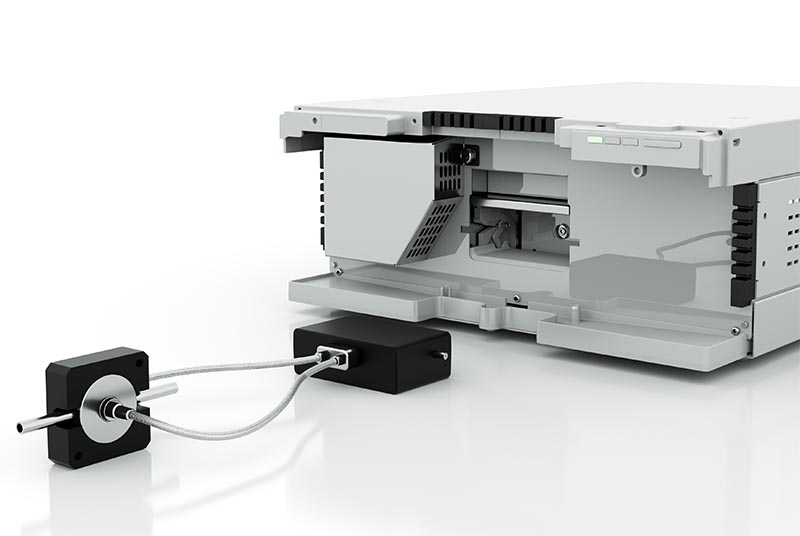

Injection Pump

Injection Pump

When the quantity of product to be injected becomes important and when having to use a syringe and multiply the injections for a single purification becomes constraining, the injection pump is the ideal tool. You just have to prime the pump with the product and then launch the method. It’s as easy as that!

Purification & testing for cannabis and hemp

Hemp contains hundreds of cannabinoids with Cannabidiol (CBD) being the most prevalent in the plant and Δ9-Tetrahydrocannabinol (THC) being the active ingredient causing psychotropic effects. However, many more compounds are formed by the hemp plant and have been investigated for their medical effects. This limit often requires THC remediation of the distilled hemp extract (starting material) and can be achieved using preparative scale chromatography such as the puriFlashR XL-Cannabis system. HPLC analysis of the starting material (third pass distillate), fractions collected during the remediation process, and the finished product can be performed using the Advion AVANT HPLC-UV analytical system. Both the purification and analytical processes are shown in this application note to form a complete solution for THC remediation in the hemp industry.

Hemp contains hundreds of cannabinoids with Cannabidiol (CBD) being the most prevalent in the plant and Δ9-Tetrahydrocannabinol (THC) being the active ingredient causing psychotropic effects. However, many more compounds are formed by the hemp plant and have been investigated for their medical effects. This limit often requires THC remediation of the distilled hemp extract (starting material) and can be achieved using preparative scale chromatography such as the puriFlashR XL-Cannabis system. HPLC analysis of the starting material (third pass distillate), fractions collected during the remediation process, and the finished product can be performed using the Advion AVANT HPLC-UV analytical system. Both the purification and analytical processes are shown in this application note to form a complete solution for THC remediation in the hemp industry.

- puriFlah® L-Canabis instrument with the output up to 4.3 kg/day (columns up to 15 cm ID)

- puriFlah® XL-canabis instrument with the output up to 12.2 kg/day (columns up to 20 cm ID)

- Plate Express TLC Plate Reader

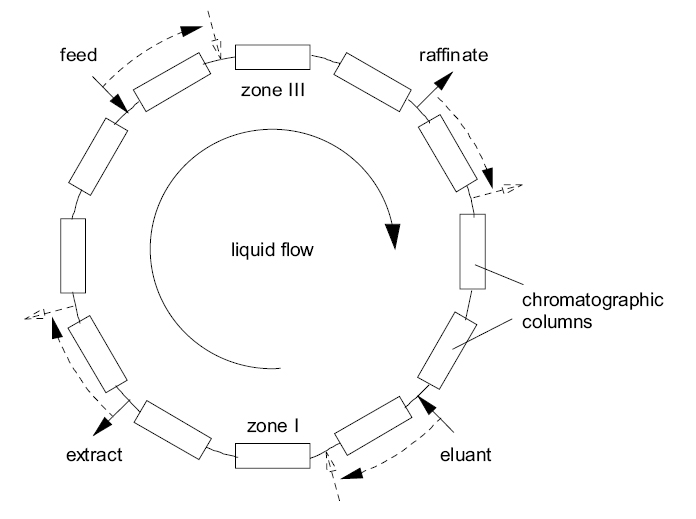

SMB

The simulated counter-current process (Simulated Moving Bed - SMB) was developed in the early 60th by the Universal Oil Products Company. It was mainly applied to industrial-scale separations, like the xylene separation or the fructose-glucose separation.

There is a strong analogy between the SMB and the TMB process. Under the use of a suitable system of adsorbent and eluent, a feed stream is separated into two withdrawal streams containing the pure components of a binary or pseudo-binary mixture.In the SMB process a large column is divided into a finite number of small sections. A withdrawal tube is situated between two of such sections.These tubes are connected in a cyclic mode with the inlets and outlets via a special designed rotary valve (Knauer). An observer sitting on an in- or outlet remarks anapparent moving of solid counter-current the fluid flow at each switching although the solid is fixed in the column. Therefore, the process is called a simulated counter-current one. The SMB is equal to TMB for an infinite numberof columns.

General principle of SMB process

0

0

0

0