Chromatography

SPE Phases

This site encloses SPE phases overview includint their technical parameters. Further information about the products are available in the product catalogue.

Clean up SPE columns

Reverse phase hydrophobic

| Phase | Pore volume (cm3/g) | Pore Size (A) | Surface Area (m2/g) | Carbon Load (%) | End Capping | Feature |

|---|---|---|---|---|---|---|

| C2 Ethyl | 0.77 | 60 | 500 | 6.6 | YES/NO | |

| C4 n-Butyl | 0.77 | 60 | 500 | 8.5 | YES | |

| C8 Octyl | 0.77 | 60 | 500 | 11.1 | YES/NO | |

| C18 Octadecyl | 0.77 | 60 | 500 | 21.7 | YES/NO | |

| C30 Tricontyl | 0.77 | 60 | 500 | 20.0 | YES | |

| Cyclohexyl | 0.77 | 60 | 500 | 11.6 | YES/NO | |

| Phenyl | 0.77 | 60 | 500 | 11.0 | YES/NO |

Normal phase hydrophilic

| Phase | Pore volume (cm3/g) | Pore Size (A) | Surface Area (m2/g) | Carbon Load (%) | Feature | |

|---|---|---|---|---|---|---|

| Silica | 0.77 | 60 | 500 | N/A | ||

| Diol | 0.99 | 60 | 500 | 8.0 | ||

| Cyanopropyl | 0.77 | 60 | 500 | 9.0 | ||

| Florisil | 0.82 | 60 | 500 | N/A | ||

| Alumina, Acidic | 60 | 500 | N/A | |||

| Alumina, Basic | 60 | 500 | N/A | |||

| Alumina, Neutral | 60 | 500 | N/A | |||

| Carbon | N/A | 120/140 mesh |

Ion Exchange - Anion Exchange

| Phase | Pore volume (cm3/g) | pKa | Pore Size (A) | Surface Area (m2/g) | Carbon Load (%) | Exchange (meq/g) |

|---|---|---|---|---|---|---|

| Aminopropyl (1 amine) | 0.77 | 9.8 | 60 | 500 | 6.65 | 0.31 |

| N-2 Aminoethyl (1/2 amine) | 0.77 | 10.1; 10.9 | 60 | 500 | 11.1 | 0.32 |

| Diethylamino (3 amine) | 0.77 | 10.6 | 60 | 500 | 10.6 | 0.28 |

| Quarternary Amine Chloride | 0.77 | Always charged | 60 | 500 | 8.4 | 0.25 |

| Quarternary Amine Hydroxide | 0.77 | Always charged | 60 | 500 | 8.4 | 0.25 |

| Quarternary Amine Acetate | 0.77 | Always charged | 60 | 500 | 8.4 | 0.25 |

| Quarternary Amine Formate | 0.77 | Always charged | 60 | 500 | 8.4 | 0.25 |

| Polyimine | 0.77 | Always charged | 13.5 | 0.25 |

Ion Exchange - Cation Exchange

| Phase | Pore volume (cm3/g) | pKa | Pore Size (A) | Surface Area (m2/g) | Carbon Load (%) | Exchange (meq/g) |

|---|---|---|---|---|---|---|

| Carboxylic Acid | 0.77 | 4.8 | 60 | 500 | 9.2 | 0.17 |

| Propylsulfonic Acid | 0.77 | 1 | 60 | 500 | 7.1 | 0.18 |

| Benzenesulfonic Acid | 0.77 | Always charged | 60 | 500 | 11.0 | 0.32 |

| Benzenesulfonic Acid, High Load | 0.77 | Always charged | 60 | 500 | 15.0 | 0.65 |

| Triacetic Acid | 0.77 | 60 | 500 | 7.61 | Anion 0.17/Cation 0.06 |

Copolymeric phases

| Phase | Pore volume (cm3/g) | pKa | Pore Size (A) | Surface Area (m2/g) | Carbon Load (%) | Exchange (meq/g) |

|---|---|---|---|---|---|---|

| Aminopropyl + C8 | 0.77 | 9,8 | 60 | 500 | 12,3 | 0,163 |

| Quarternary Amine + C8 | 0.77 | Always charged | 60 | 500 | 13,6 | 0,160 |

| Carboxylic Acid + C8 | 0.77 | 4,8 | 60 | 500 | 2,5 | 0,105 |

| Propylsulfonic Acid + C8 | 0.77 | 1 | 60 | 500 | 14,62 | 0,114 |

| Benzenesulfonic Acid + C8 | 0,77 | Always charged | 60 | 500 | 12.3 | 0,072 |

| Cyanopropyl + C8 | 0,77 | N/A | 60 | 500 | 14,6 | 0,163 |

| Cyclohexyl + C8 | 0.77 | N/A | 60 | 500 | N/A | N/A |

GC Phases

On this page we provide an overview of the supplied stationary phases for gas chromatography (GC). Each is given details of its properties and the applications that are suitable for them. In the product catalog you can then choose a suitable quartz or metal capillary column for GC.

Stationary phases LION

Fused silica capillary columns

| Stationary phase | Temperature range | Composition | USP Phase |

|---|---|---|---|

| LN-1 | -60 to 370°C | 100% dimethyl polysiloxane | G2 |

| LN-1 MS | -60 to 370°C | 100% dimethyl polysiloxane | G2 |

| LN-1 HT | -60 to 430°C | 100% dimethyl polysiloxane | - |

| LN-5 | -60 to 370°C | 5% diphenyl/95% dimethyl polysiloxane | G27 |

| LN-5 Sil MS | -60 to 370°C | 5% diphenyl/95% dimethyl polysiloxane | G27 |

| LN-5 MS | -60 to 350°C | 5% phenyl - arylene - 95% dimethyl polysiloxane | G27 |

| LN-5 HT | -60 to 430°C | 5% diphenyl/95% dimethyl polysiloxane | - |

| LN-35 | 50 to 360°C | 35% diphenyl/65% dimethyl polysiloxane | G42 |

| LN-35 HT | -60 to 400°C | 35% diphenyl/65% dimethyl polysiloxane | G42 |

| LN-17 | 40 to 340°C | 50% diphenyl/50% dimethyl polysiloxane | G3 |

| LN-624 | -20 to 260°C | 6% cyanopropylphenyl/94% dimethyl polysiloxane | G43 |

| LN-FFAP | 40 to 260°C | Nitroterephthalic Acid Modified Polyethylene Glycol | G35 |

| LN-1701 | -20 to 300°C | 14% cyanopropylphenyl/86% dimethyl polysiloxane | G46 |

| LN-XLB | 30 to 360°C | Low polarity phases | - |

| LN-XLB-HT | 30 až 400°C | Low polarity phases | |

| LN-WAX | 40 to 260°C | Polyethylene Glycol | G16 |

| LN-WAX Plus | 20 to 260°C | Polyethylene Glycol | G16 |

UHPLC

Ultra-High Performance Liquid Chromatography a milestone in the evolution of LC in that columns packed with <2µm particles, used with instrumentation capable of handling the resulting high back pressures, make possible extremely fast and efficient separations. UHPLC is a very powerful tool for today’s practicing chromatographer, as it can significantly increase the efficiency of a chromatographic separation. In addition, the wider range of usable flow rates makes high speed separations possible.

Ultra-High Performance Liquid Chromatography a milestone in the evolution of LC in that columns packed with <2µm particles, used with instrumentation capable of handling the resulting high back pressures, make possible extremely fast and efficient separations. UHPLC is a very powerful tool for today’s practicing chromatographer, as it can significantly increase the efficiency of a chromatographic separation. In addition, the wider range of usable flow rates makes high speed separations possible.

- Instruments

- UHPLC Columns

- UHPLC Performance on any LC instrument

- Applications and support

- Reagents

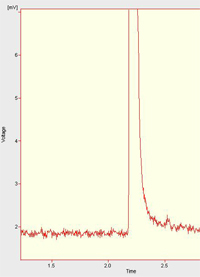

Effect on efficience

The lower the particle size, the higher column efficience is (see graph below). With particle size decrease the column back pressure increases significantly. This leads to ultra high pressure of longer LC columns. It means that we cannot use 1,9µm UHPLC column the same lenth like 5µm column (eg. 250 mm long column). In the end we have lower or similar column efficieny as we have with standard HPLC columns. The main benefit of the UHPLC columns is the analysis run time, not the efficiency.

If you need to increase efficiency, look at phase chemistry first. In this case look at stationary phase list.

UHPLC Phases

Raptor - RESTEK

| Packing Material | Particle Size (µm) | Pore Size (Å) | Effective Surface Area (m2/g) | Carbon Load (%) | pH Range |

|---|---|---|---|---|---|

| Raptor ARC-C18 | 1.8 | 90 | 125 | proprietary | 1.0-8.0 |

| Raptor ARC-C18 | 2.7 | 90 | 130 | proprietary | 1.0-8.0 |

| Raptor ARC-C18 | 5.0 | 90 | 100 | proprietary | 1.0-8.0 |

| Raptor C18 | 1.8 | 90 | 125 | proprietary | 2.0-8.0 |

| Raptor C18 | 2.7 | 90 | 130 | proprietary | 2.0-8.0 |

| Raptor C18 | 5.0 | 90 | 100 | proprietary | 2.0-8.0 |

| Raptor Biphenyl | 1.8 | 90 | 125 | proprietary | 1.5-8.0 |

| Raptor Biphenyl | 2.7 | 90 | 130 | proprietary | 1.5-8.0 |

| Raptor Biphenyl | 5.0 | 90 | 100 | proprietary | 1.5-8.0 |

| Raptor Fluorophenyl | 1.8 | 90 | 125 | proprietary | 2.0-8.0 |

| Raptor Fluorophenyl | 2.7 | 90 | 130 | proprietary | 2.0-8.0 |

| Raptor Fluorophenyl | 5.0 | 90 | 100 | proprietary | 2.0-8.0 |

| Raptor HILIC-Si | 2.7 | 90 | 150 | n/a | 2.0-8.0 |

| Raptor EtG/EtS | 2.7 | 90 | 130 | proprietary | 2.0-8.0 |

Raptor maximum pressure: 1,034 bar (1.8 μm), 600 bar (2.7 μm); 400 bar (5 μm). For maximum lifetime recommended maximum pressure for 1.8 µm particles is 830 bar.

PINNACLE DB - RESTEK

| Packing Material | Particle Size (µm) | Pore Size (Å) | Surface Area (m2/g) | Carbon Load (%) | pH Range |

|---|---|---|---|---|---|

| Pinnacle DB C18 | 1.9 | 140 | 150 | 11 | 2.5-8.0 |

| Pinnacle DB Aqueous C18 | 1.9 | 140 | 150 | 6 | 2.5-8.0 |

| Pinnacle DB C8 | 1.9 | 140 | 150 | 6 | 2.5-8.0 |

| Pinnacle DB CN | 1.9 | 140 | 150 | 4 | 2.5-8.0 |

| Pinnacle DB PFP | 1.9 | 140 | 150 | 6 | 2.5-8.0 |

| Pinnacle DB Biphenyl | 1.9 | 140 | 150 | 8 | 2.5-8.0 |

| Pinnacle DB IBD | 1.9 | 140 | 150 | proprietary | 2.5-8.0 |

| Pinnacle DB Silica | 1.9 | 140 | 150 | n/a | 2.5-8.0 |

Troubleshooting

Many GC and LC problems can be avoided with routine preventive maintenance. If you are seeking the cause of the chromatography problem, go step by step. Never make more changes in your instrument at the same time, otherwise you will never find, what caused the problem.

Select your category of chromatography to read more about the troubleshooting:

GC troubleshooting

LC troubleshooting

dSPE (QuEChERS)

Resprep™ QuEChERS Products

QuEChERS Tubes For Extraction and Clean-Up of Pesticide Residues From Food Products

- Fast, simple sample extraction and cleanup using dSPE.

- Fourfold increases in sample throughput.

- Fourfold decreases in material cost.

- Convenient, ready to use centrifuge tubes with ultra pure, preweighed adsorbent mixes.

Quick, Easy, Cheap, Effective, Rugged, and Safe, the QuEChERS ("catchers") method is based on work done and published by the US Department of Agriculture Eastern Regional Research Center in Wyndmoor, PA.(1) Researchers there were looking for a simple, effective, and inexpensive way to extract and clean pesticide residues from the many varied sample matrices with which they routinely worked. They had been using the Modified Luke Extraction Method, which is highly effective and rugged, but is both labor and glassware intensive, leading to a relatively high cost per sample. Solid phase extraction also had been effective, but the complex matrices the investigators were dealing with required multiple individual cartridges and packings to remove the many classes of interferences, adding costs and complexity to the process. A new method would have to remove sugars, lipids, organic acids, sterols, proteins, pigments and excess water, any of which often are present, but still be easy to use and inexpensive.

Quick, Easy, Cheap, Effective, Rugged, and Safe, the QuEChERS ("catchers") method is based on work done and published by the US Department of Agriculture Eastern Regional Research Center in Wyndmoor, PA.(1) Researchers there were looking for a simple, effective, and inexpensive way to extract and clean pesticide residues from the many varied sample matrices with which they routinely worked. They had been using the Modified Luke Extraction Method, which is highly effective and rugged, but is both labor and glassware intensive, leading to a relatively high cost per sample. Solid phase extraction also had been effective, but the complex matrices the investigators were dealing with required multiple individual cartridges and packings to remove the many classes of interferences, adding costs and complexity to the process. A new method would have to remove sugars, lipids, organic acids, sterols, proteins, pigments and excess water, any of which often are present, but still be easy to use and inexpensive.

The researchers developed a simple two-step procedure. First, the homogenized samples are extracted and partitioned, using an organic solvent and salt solution. Then, the supernatant is further extracted and cleaned, using a dispersive SPE technique. Multiple adsorbents are placed in a centrifuge tube, along with the 1mL of organic solvent and the extracted residues partitioned from step 1. The contents are thoroughly mixed, then centrifuged, producing a clean extract ready for a variety of GC or HPLC analytical techniques.(2) Validation and proficiency data for the QuEChERS method are available for a wide variety of pesticides in several common food matrices at www.quechers.com.

Using the dispersive SPE approach, the quantity and type of adsorbents, as well as the pH and polarity of the solvent, can be easily adjusted for differing matrix interferences and "difficult" analytes. Results from this approach have been verified and modified at several USDA and Food and Drug Administration labs, and the method now is widely accepted for many types of pesticide residue samples.

Restek products make this approach even simpler. The centrifuge tube format, available in 2mL and 15mL sizes, contains magnesium sulfate (to partition water from organic solvent) and PSA* adsorbent (to remove sugars and fatty acids), with or without graphitized carbon (to remove pigments and sterols) or C18 packing (to remove nonpolar interferences). Custom products are available by quote request. If you are frustrated by the time and cost involved with your current approach to pesticide sample cleanup, we suggest you try this simple and economical new method.

We have products compliant with AOAC, Multi-miniresidue and Draft European methods.

Inforamtion about products is available here.

References:

- Anastassiades, M., S.J. Lehotay, D. Stajnbaher, F.J. Schenck, Fast and Easy Multiresidue Method Employing Acetonitrile Extraction/Partitioning and "Dispersive Solid-Phase Extraction" for the Determination of Pesticide Residues in Produce, J AOAC International, 2003, vol 86 no 22, pp 412-431.

- Schenck, F.J., SPE Cleanup and the Analysis of PPB Levels of Pesticides in Fruits and Vegetables. Florida Pesticide Residue Workshop, 2002

MEPS Phases

SGE

| Phase | Particle size (µm) | Pore Size (A) |

|---|---|---|

| Silica | 45 | 60 |

| C2 | 45 | 60 |

| C8 | 45 | 60 |

| C8+SCX* | 45 | 60 |

| C18 | 45 | 60 |

*C8+SCX BINS are labelled as M1.

The BINs can be used up to 40 - 100 extractions. General preparation time is 1 - 2 minutes.

Stationary phases

Chromatography, either GC, HPLC, SPE, FLASH or preparative, uses many types of stationary phases. Here you wil find detailed information about stationary phases.

Chromatography, either GC, HPLC, SPE, FLASH or preparative, uses many types of stationary phases. Here you wil find detailed information about stationary phases.

Stationary phases for analytical separation

Stationary phases for sample preparation

- SPE

- dSPE (QuEChERS)

- IAC (Immunoaffinity Columns)

- MEPS (Micro Extraction by Packed Sorbent)

- FLASH

- BULK (media for preparative chromatography)

Glossary

- BEH = Bridged ethyl hybrid (HPLC particle)

- DAC = dynamic axial compression

- DAD = diod array detector

- ECD = electron capture detector

- EI = electron ionization

- ELSD = evaporative light scattering detector

- FIA = flow injection analysis

- FID = flame ionization detector

- FPD = flame photometric detector

- FPP = fully porous particles

- GC = gas chromatography

- GCTQ = gas chromatographs with Triple Stage Quadrupole

- GCxGC = multidimensional gas chromatography

- GPC = gel permeation chromatography

- HETP = height equivalent of theoretical plate

- HID = helium ionization detector

- HILIC = hydrophobic interaction liquid chromatography

- HPLC = high performance liquid chromatography

- HPTLC = high performance thin layer chromatography

- IC = ion chromatography

- IHPLC = intermediate high performance liquid chromatography

- LVI = large volume injection

- MCSGP = Multicolumn countercurrent solvent gradient purification

- MEPS = Micro Extraction by Packed Sorbent

- MLC = micellar liquid chromatography

- MS = mass spectrometry

- MSPE = Micro SPE

- NP = normal phase

- NQAD = Nano Quantity Analyte Detector

- ODS = octa decyl silicagel

- PDD = pulsed discharged detector

- PFPD = pulsed flame photometric detector

- PID = photo ionization detector

- PTV = programmable temperature vapourizer

- RI = refractive index

- RP = reversed phase

- RRLC = rapid resolution liquid chromatography

- SBSE = Stirring Bar Sorbent Extraction

- SEC = size exclusion chromatography

- SFC = supercritical fluid chromatography

- SIM = single ion monitoring

- SMB = simulated moving bed

- SPE = solid phase extraction

- SPP = superficially porous particles (core-shell)

- SPME = solid phase micro extraction

- TCD = thermal conductivity detector

- TIC = total ion current

- TLC = thin layer chromatography

- TOF = MS analyzer "Time of Flight"

- UFLC = ultra fast liquid chromatography

- UPLC = ultra performance liquid chromatography

- UHPLC = ultra high pressure liquid chromatography, ultra high performance liquid chromatography

Signal to noise ration improvment in GC

Today's laboratory needs are:

Today's laboratory needs are:

- Lower detection and quantitation limits (LOD, LQD)

- Stability improvment in GC and GC/MS systems

- More inert and stable GC parts (columns, septa, vials, liners, ...)

Lower detection and quantitation limits can be achieved by:

- Reducing the Noise

- Increasing the signal

0

0

0

0