0

Сравнивать

0

Сравнивать

Пользователь

Пользователь

0

Корзина

0

Корзина

Подготовка проб

A

Argolab Ultrasonic baths

Новые ультразвуковые ванны Argolab доступны в аналоговом или цифровом исполнении. Более подробную информацию вы найдете в техническом паспорте. Нажмите на картинку для скачивания.

Новые ультразвуковые ванны Argolab доступны в аналоговом или цифровом исполнении. Более подробную информацию вы найдете в техническом паспорте. Нажмите на картинку для скачивания.

C

Catalog of consumables for dissolution

Download catalog here.

G

H

Hamilton - Инструкции по уходу и использованию шприцев

Шприцы Hamilton являются одними из самых качественных дозаторов для точного дозирования жидкостей. При правильном уходе и обращении он прослужит вам долгие годы. Жидкость в шприце проходит только через химически инертные материалы.

Шприцы и иглы производства компании Hamilton предназначены только для научных исследований и лабораторного использования и не предназначены для использования человеком in vivo.

В прилагаемом руководстве вы найдете информацию о безопасном использовании шприцев и советы по устранению неполадок на английском языке.

- Syringe_Care-and-Use-Guide

3235 kB

Hamilton Syringes and Needles Catalolgue

Компания Hamilton запустила новый каталог шприцев и игл для хроматографии. Вы можете скачать его, нажав на картинку.

- Syringe_Needle_Reference-Guide

10888 kB

M

MSPE Compatibility with the liquids

Below you will find information about the chemical compatibility of our MSPE column materials with various types of liquids.

S

SKC Step by Step Guide

Полезное вводное руководство по основам отбора проб воздуха и рекомендации по отбору проб воздуха, в котором представлена информация об отборе проб пыли и паров/газов, а также об используемом оборудовании и методах. Продукты, упомянутые в этом материале, подходят для большинства случаев. Конкретные методы отбора проб можно найти на нашем веб-сайте www.chromservis.eu в разделе «Отбор проб».

Ниже вы найдете руководство по отбору проб.

- SKC sprievodca vzorkovaním komplet_SK

1445 kB - SKC Step by Step Guide

4104 kB

U

UTC - Improved Hydrocarbon Fractionation Using a Novel Silver-Phase SPE Sorbent

Download catalog here.

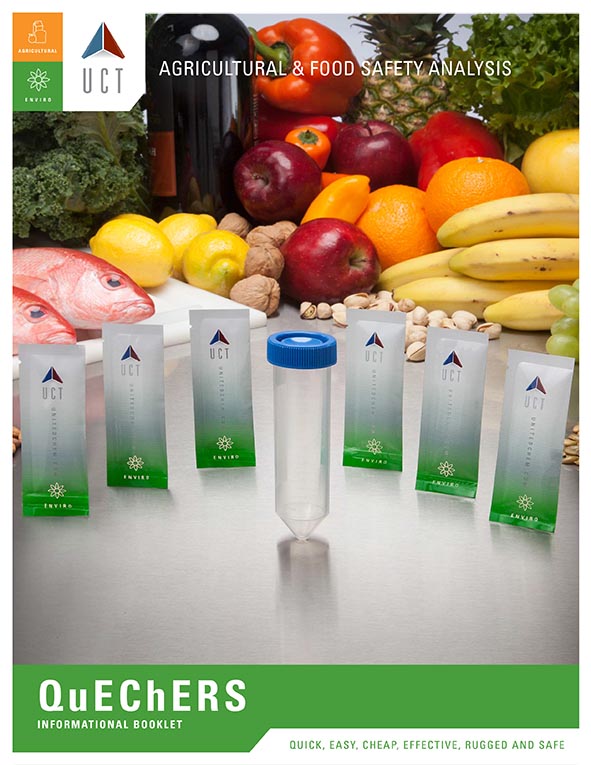

UTC Applications using Quechers

UTC Applications using Quechers

QuEChERS is the shortcut for Quick, Easy, Cheap, Effective, Rugged and Safe. It is a sample extraction and clean-up technique widely used for the analysis of multiple residues in hydrated agricultural products. Originally designed for the analysis of fruits and vegetables, QuEChERS now includes a wide range of agricultural products. It combines several sample preparation steps and extends the range of analytes recovered over older, tedious extraction methods. A driving force in the growth of QuEChERS is the emerging need to determine trace amounts of analytes in a high throughput environment.

Click at the picture to download the brochure.

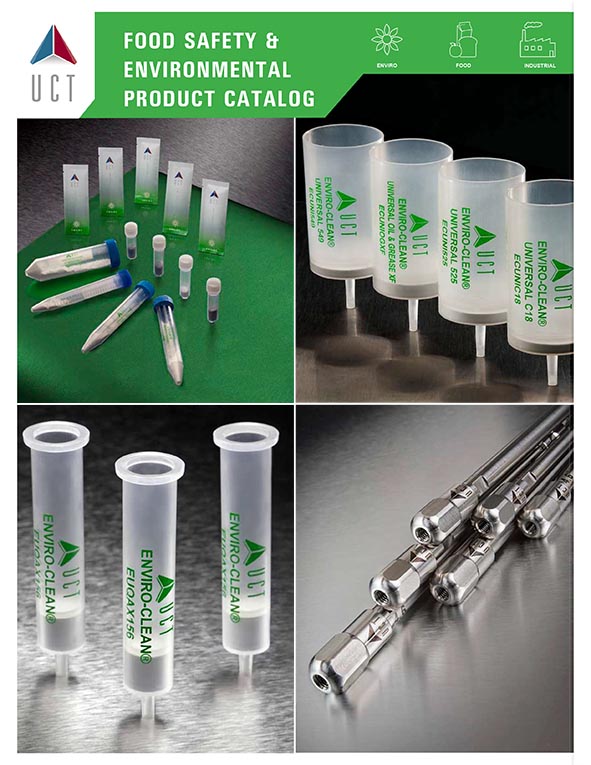

UTC Product catalog for environmental analysis

UTC Product catalog for environmental analysis

Founded in 1986, UCT has grown to be a respected leader in the drug testing, pharmaceutical, clinical, environmental and agricultural industries. Our wide range of highly reproducible solid-phase extraction columns allow the chromatographer a consistent extraction technique, and our expertise in silane manufacturing allows greater control of the chemical processes involved in producing our high quality bonded phases. We manufacture our complete product line of bonded silica sorbents, packaged in a variety of formats, including SPE columns, 96 & 48 well plates, Universal cartridges and micro-centrifuge tubes.

Click at the picture to download the brochure.

Environmental applications

Application manual for analysis of environmental and food samples here.

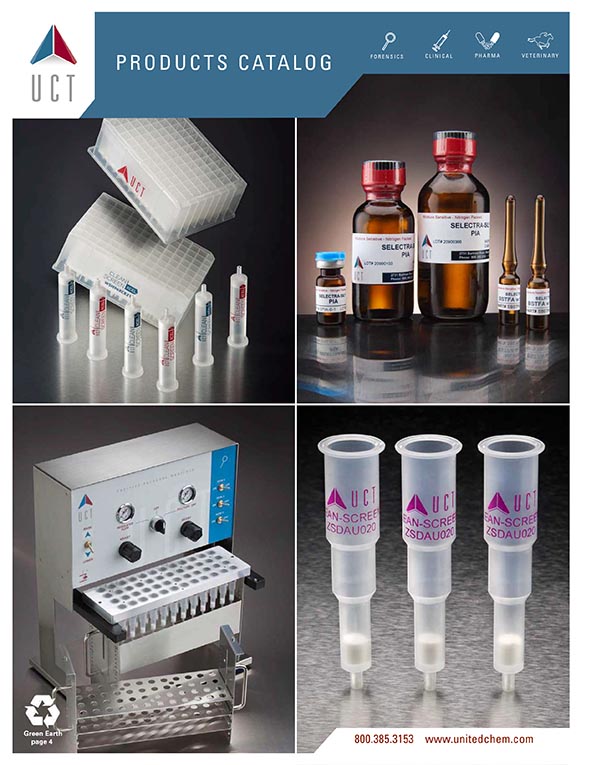

UTC Product catalog for forensic analysis

UTC Product catalog for forensic analysis

Founded in 1986, UCT has grown to be a respected leader in the drug testing, pharmaceutical, clinical, environmental and agricultural industries. Our wide range of highly reproducible solid-phase extraction columns allow the chromatographer a consistent extraction technique, and our expertise in silane manufacturing allows greater control of the chemical processes involved in producing our high quality bonded phases. We manufacture our complete product line of bonded silica sorbents, packaged in a variety of formats, including SPE columns, 96 & 48 well plates, Universal cartridges and micro-centrifuge tubes.

Click at the picture to download the brochure.

Forensic applications

Application manual for analysis of forensis, biochemic and clinic samples here.

V

Vicam - каталог

VICAM специализируется на диагностических решениях в области контроля и защиты пищевых продуктов, а также качества кормов. Вот почему VICAM опубликовал очень красивый и понятный каталог, в котором вы найдете не только иммуноаффинные колонки для анализа целого ряда микотоксинов, но и диагностические наборы, которые отличаются простотой и скоростью и подходят для небольших лабораторий на фермах. и везде, где хранятся сельскохозяйственные продукты.

- VICAM_ProductGuide_2023

5795 kB

Vicam - контроль качества продуктов, содержащих каннабиноиды

Каннабиноиды в последнее время используются как в медицине, так и в косметических продуктах. Чтобы гарантировать качество продуктов с каннабиноидами, также проверяется содержание микотоксинов. Здесь вы можете скачать брошюру, посвященную контролю качества продуктов, содержащих каннабиноиды.

Каннабиноиды в последнее время используются как в медицине, так и в косметических продуктах. Чтобы гарантировать качество продуктов с каннабиноидами, также проверяется содержание микотоксинов. Здесь вы можете скачать брошюру, посвященную контролю качества продуктов, содержащих каннабиноиды.

К

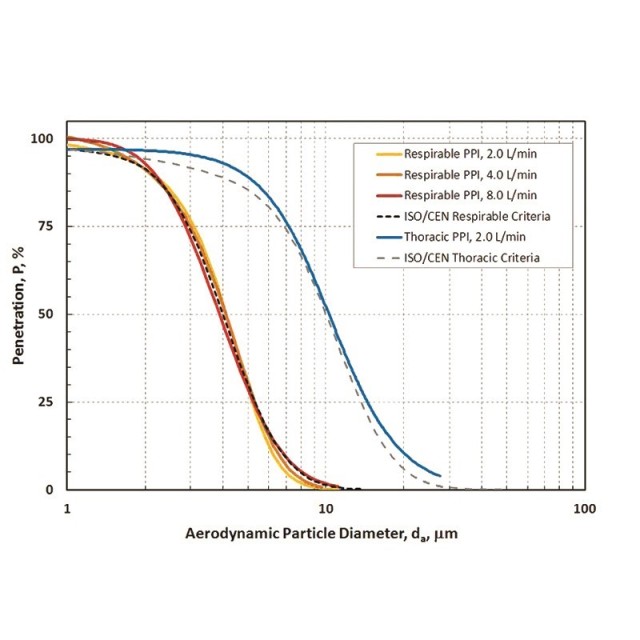

Каталог SKC – обзор всей продукции для сбора пыли и загрязняющих веществ.

Ниже вы можете скачать полный каталог продукции SKC. В нем вы найдете пробоотборные устройства и другие аксессуары для отбора проб пыли и загрязняющих веществ, такие как пробоотборные головки, сорбционные трубки, фильтры, пассивные пробоотборники, мешки. В каталоге также содержится обзор веществ, которые можно принимать, как их можно принимать и, возможно, какая методология к ним применима. Мы будем рады помочь Вам с выбором и ответить на Ваши вопросы по данному вопросу.

Коробки MSPE

Колонки Microspin (MSPE) используются для предварительной обработки проб в качестве замены колонок для ТФЭ. Колонка MSPE состоит из внутреннего микроспинового фильтра с мембраной 0,22 мкм, над которым размещены сорбент и внешние центрифужные пробирки. Мембрана может быть изготовлена из нейлона, ПТФЭ (гидрофильного и гидрофобного), ПВДФ и ацетилированной целлюлозы. Это простой и быстрый метод пробоподготовки, который использует мембранную фильтрацию 2-в-1 и экстракцию сорбентом в один этап. Колонки MSPE широко используются в клинической биохимии, токсикологии, нейроиммунологии и биотехнологии. Не стесняйтесь обращаться к нам за дополнительной информацией.

- MSPE_brochure-ver3en

2148 kB

Н

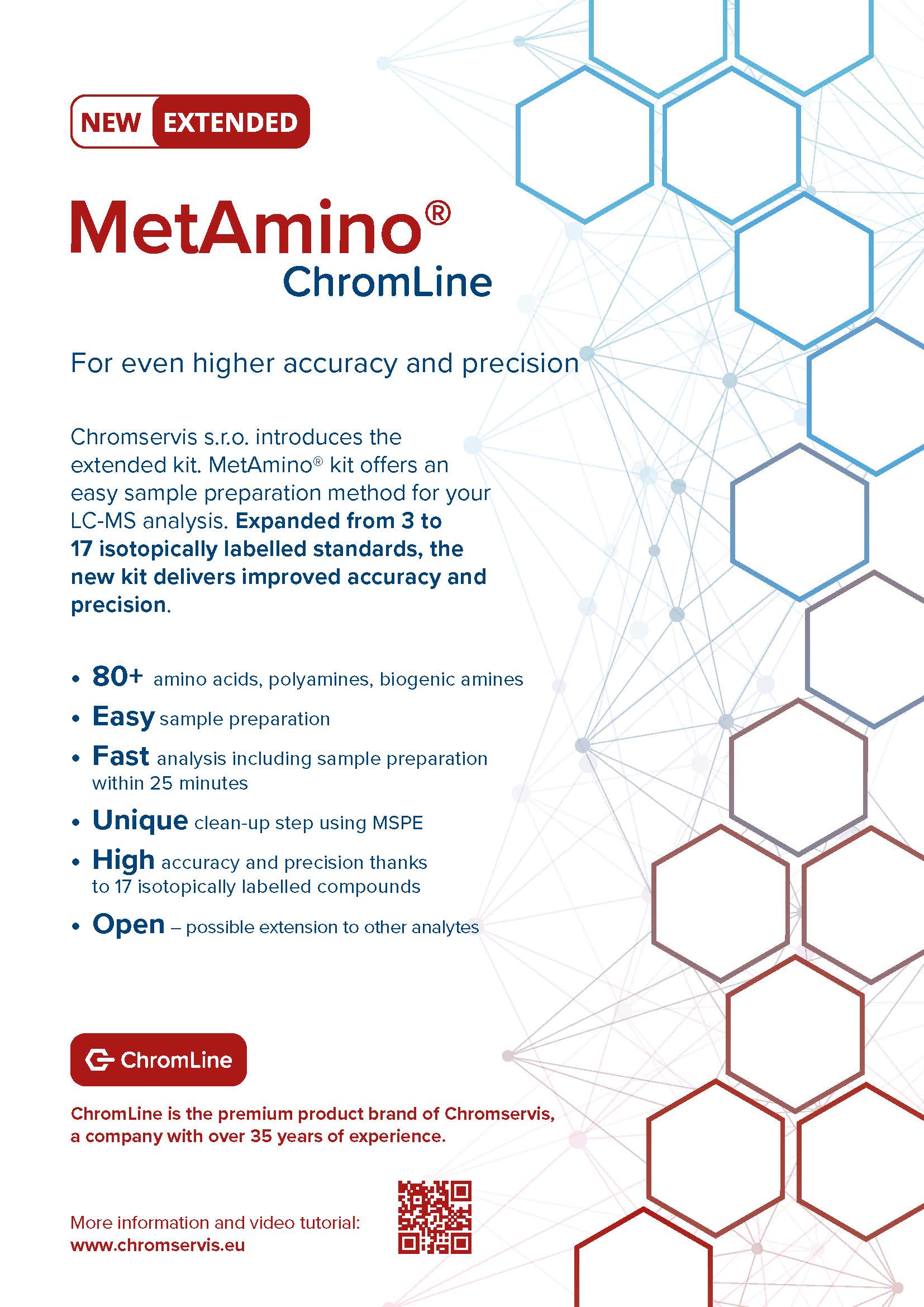

Набор MetAmino

Наборы MetAmino® предлагают простой метод подготовки образцов для анализа LC-MS или GC-MS. Наборы MetAmino® содержат дериватизационные реагенты и все принадлежности для очистки, необходимые для подготовки образца к инъекции. Они устраняют трудоемкие процедуры подготовки образцов. Новый метод очистки использует в качестве последнего шага специальный материал, включая фильтрацию (нет необходимости использовать инъекционный фильтр перед инъекцией). Дополнительным преимуществом является то, что процесс дериватизации позволяет расширить список анализируемых веществ.

Наборы MetAmino® предлагают простой метод подготовки образцов для анализа LC-MS или GC-MS. Наборы MetAmino® содержат дериватизационные реагенты и все принадлежности для очистки, необходимые для подготовки образца к инъекции. Они устраняют трудоемкие процедуры подготовки образцов. Новый метод очистки использует в качестве последнего шага специальный материал, включая фильтрацию (нет необходимости использовать инъекционный фильтр перед инъекцией). Дополнительным преимуществом является то, что процесс дериватизации позволяет расширить список анализируемых веществ.

💡Набор для LC-MS содержит 17 изотопно меченных стандартов и предлагает анализ более 80 аминокислот, полиаминов и биогенных аминов.

🔗Для получения более подробной информации свяжитесь с нами.

- 26_02_MetAmino_extended

357 kB