Nafion dryers

Perma Pure LLC manufactures components and devices primarily designed to dry and humidify gas streams. The core technology is Nafion®, a Dupont co-polymer that is highly selective in the removal of water. Perma Pure manufactures Nafion into tubing of various diameters to optimize the transfer of water through the Nafion. The water moves through the membrane wall and evaporates into the surrounding air or gas in a process called perevaporation. This process is driven by the humidity gradient between the inside and the outside of the tubing. In addition to drying and humidifying, our products can be used as ion exchange membranes and specialty separation membranes that take advantage of the unique properties of Nafion.

Perma Pure LLC manufactures components and devices primarily designed to dry and humidify gas streams. The core technology is Nafion®, a Dupont co-polymer that is highly selective in the removal of water. Perma Pure manufactures Nafion into tubing of various diameters to optimize the transfer of water through the Nafion. The water moves through the membrane wall and evaporates into the surrounding air or gas in a process called perevaporation. This process is driven by the humidity gradient between the inside and the outside of the tubing. In addition to drying and humidifying, our products can be used as ion exchange membranes and specialty separation membranes that take advantage of the unique properties of Nafion.

What is Nafion?

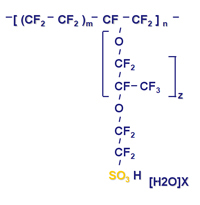

Nafion is a copolymer of tetrafluoroethylene (Teflon®) and perfluoro-3,6-dioxa-4-methyl-7-octene-sulfonic acid. Like Teflon, Nafion is highly resistant to chemical attack, but the presence of its exposed sulfonic acid groups confers unusual properties. Sulfonic acid has a very high water-of-hydration, absorbing 13 molecules of water for every sulfonic acid group in the polymer; consequently, Nafion absorbs 22% by weight of water.

Nafion is a copolymer of tetrafluoroethylene (Teflon®) and perfluoro-3,6-dioxa-4-methyl-7-octene-sulfonic acid. Like Teflon, Nafion is highly resistant to chemical attack, but the presence of its exposed sulfonic acid groups confers unusual properties. Sulfonic acid has a very high water-of-hydration, absorbing 13 molecules of water for every sulfonic acid group in the polymer; consequently, Nafion absorbs 22% by weight of water.

Unlike micro-porous membrane permeation, which transfers water through a relatively slow diffusion process, Nafion removes water by absorption as water-of-hydration. This absorption occurs as a First Order Kinetic reaction, so equilibrium is reached very quickly (typically with in milliseconds). Because this is a specific chemical reaction with water, gases being dried or processed are usually entirely unaffected.

Selectivity

Nafion is not only highly resistant to chemical attack, it also exhibits highly selective absorption and transfer of compounds. Most substances are retained quantitatively. Although they do not attack or damage the Nafion tubing, some polar organic substances are absorbed and consequently lost. Ammonia and amines are also absorbed and lost to some degree.

Temperature, Pressure and Chemical Resistance

Nafion tubing is very stable at high temperatures. As noted previously, its chemical resistance is similar to Teflon, and very few things can attack it. Even samples containing high concentrations of very corrosive gases like hydrogen fluoride or hydrogen chloride can be dried or processed. In addition to the Nafion tubing, most Perma Pure dryers and humidifiers include a shell to contain the purge gas as well as fittings for gas connections to the gas stream and purge lines. Shells and fittings are available in stainless steel, fluorocarbon polymer, or polypropylene. For higher gas stream flow rates, bundles of Nafion tubing are formed using chemically resistant thermosetting epoxy resin. The temperature resistance properties of the dryers are dependent on these other materials as well. The gas stream does not come into contact with the shell but the fittings for gas stream connection do contact the gases.

Nafion tubing is very stable at high temperatures. As noted previously, its chemical resistance is similar to Teflon, and very few things can attack it. Even samples containing high concentrations of very corrosive gases like hydrogen fluoride or hydrogen chloride can be dried or processed. In addition to the Nafion tubing, most Perma Pure dryers and humidifiers include a shell to contain the purge gas as well as fittings for gas connections to the gas stream and purge lines. Shells and fittings are available in stainless steel, fluorocarbon polymer, or polypropylene. For higher gas stream flow rates, bundles of Nafion tubing are formed using chemically resistant thermosetting epoxy resin. The temperature resistance properties of the dryers are dependent on these other materials as well. The gas stream does not come into contact with the shell but the fittings for gas stream connection do contact the gases.

For our single tube MD-Series gas dryers, the maximum temperature for polypropylene shells and fittings is 100°C, and 150°C for fluorocarbon and stainless steel. When Nafion tubing bundles are used, the epoxy limits the maximum temperature to 120°C. The maximum internal pressure for all dryers is usually limited by the Nafion tubing to 80 psig at 20°C. Recent advances in some specialty dryers have increased this pressure tolerance.

Dryers and humidifiers with single strands of Nafion tubing tolerate any gas stream that its fittings tolerate. Dryers and humidifiers with Nafion tubing bundles are somewhat more sensitive due to the epoxy resin used to channel the gas stream into each tube. Perma Pure's technical staff will verify the acceptability of highly corrosive sample.

Proven Technology

Perma Pure developed the first Nafion dryers more than twenty-five years ago. Today Perma Pure dryers are used throughout the world for gas sample conditioning prior to analysis by medical, scientific, and industrial instrumentation. This drying technology is branching out from the sampling environment into the process world, with applications ranging from medical drying to industrial process drying of various gases. Perma Pure humidifiers are also evolving from the analytical and laboratory arena to function as specialty humidifiers in applications ranging from medical gas humidification to humidifying hydrogen for fuel cells. In every application, Perma Pure products are guaranteed to perform reliably every time.

0

0

0

0